Trantech Mobile Auxiliary Cooling

/Transformers need to be cooled to dissipate the heat generated during their operation. When electricity flows through the windings of a transformer, it encounters electrical resistance, which causes some energy to be converted into heat. Additionally, magnetic losses also contribute to heat generation in the core of the transformer.

The amount of heat produced in a transformer depends on factors such as the transformer's size, load current, and the efficiency of its design. If the heat is not properly managed, it can lead to a rise in temperature, which can be detrimental to the transformer's performance and longevity.

Excessive heat can cause several issues in transformers, including:

Reduced Efficiency

Degraded Insulation

Shortened Lifespan

Stein industries LArge power transformer equipped with enourmous trantech radiators ready to be shipped to our customer

To prevent these problems, transformers are designed with cooling systems that help dissipate the heat effectively. There are various cooling methods used in transformers, including:

Air Cooling: Smaller transformers and those with lower power ratings are typically air-cooled using natural convection or forced air fans.

Oil Cooling: Many medium and large power transformers use oil as a coolant. The oil carries away the heat from the transformer's windings and core and is circulated through cooling radiators to dissipate the heat to the surrounding air.

Liquid Cooling: In some high-power and special applications, liquid coolants such as water or synthetic liquids are used to remove the heat from the transformer.

By maintaining proper cooling, transformers can operate efficiently, have an extended service life, and provide reliable power distribution in various electrical systems.

But what happens if the cooling fails?

Transformer cooling can fail due to various reasons, and these failures can have significant consequences for the transformer's performance and longevity.

Some common reasons for transformer cooling failures include:

Cooling System Blockage: Cooling systems, such as oil or air channels, can become blocked or obstructed by debris, dirt, or foreign materials. This blockage restricts the flow of the cooling medium, reducing its ability to carry away heat from the transformer.

Pump or Fan Failure: In forced-air or liquid-cooled transformers, the failure of fans or pumps can result in inadequate cooling circulation, causing a rise in temperatures within the transformer.

Insufficient Cooling Medium: In liquid-cooled transformers, if there is a loss or insufficient quantity of cooling oil or liquid, the cooling capacity is compromised, leading to overheating.

Contaminated Cooling Medium: Contamination of the cooling oil or liquid by moisture, sludge, or impurities can reduce its heat dissipation capabilities, resulting in inadequate cooling.

Some of the more uncommon cooling failures can be a result of:

Environmental Factors: Adverse environmental conditions, such as extreme heat or cold, hail or ice can impact the cooling efficiency of transformers, especially in outdoor installations.

Mechanical Failure: external conditions such as damaging hail or ice can result in the failure or malfunction of transformer cooling systems.

Human Interference: unintentional or intentional damage to electrical equipment may result in the mechanical failure of cooling systems, rendering the transformer non-operational.

Mobile Auxiliary Cooling

Should a transformer’s cooling system fail unexpectedly, you might find yourself looking for a quick-swap, temporary solution to bring your transformer back online and restore power to your customers.

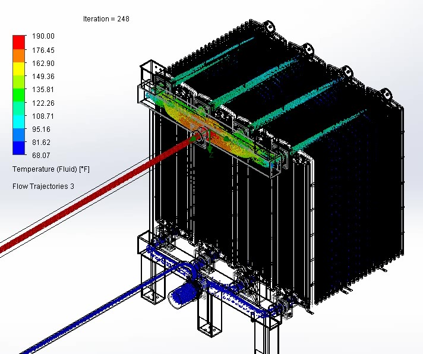

Trantech Radiator Products’ latest addition to cooling solutions is the Mobile Auxiliary Cooler (MAC). Offering a range from 40 to 215kW of cooling capacity per unit with 3-stage capability (ONAN, ONAF and OFAF). MAC units are designed to operate with most any style transformer in the harshest environments for decades. Guaranteed stock on all replacement parts that can ship same day in most cases. Trantech offers a 3-year limited warranty on all major components

Benefits

A level of protection for overheating transformers or transformers that have lost cooling capacities,

Availability of emergency cooling for short periods,

Availability of long-term cooling solutions,

Reduced downtime in the event of a terroristic attack,

Industry-known cooling methods along with industry-standard technology,

Self-contained and portable,

Customizable fan systems using Krenz or PX3 brands,

Rugged Cardinal pump available in 2 options,

HDG structure with powder-coated exterior.

Features

316SS Gate valve pre-pump / post-MAC unit,

Bolted structure made for ease of maintenance and replacement of damaged components,

Brass drain valve with DGA sampling,

Isolation valves for each radiator and manifold assembly,

316SS venting valve,

Accommodates 2” and 3” connections,

Load and unload with a forklift or crane,

Standard control box with each unit or custom control boxes to customer specifications,

Various connection flanges are available to fit most legacy transformers.

More info on Trantech products:

More info on Stein products:

Quotes, info or demo: