Valmont® Rapid Response™ Steel Distribution Poles

/If you are like many other municipal and provincial utility companies and are forced to research alternatives to your wooden distribution utility poles due to the lack of availability, or if you are looking for a sustainable, more environmentally friendly, lower lifecycle cost alternative, then we can highly recommend Valmont®’s steel poles - they don't rot, they don't get infested with bugs, and they don't require constant maintenance.

Features and Benefits

Why Valmont® Utility?

Engineer - Manufacture - Deliver

Recognized as an industry leader in quality and reliability, Valmont® has been supplying utility structures since the 1970s. Dependable structures are a priority and Valmont® utilizes proprietary engineering design software, developed in-house and based on extensive testing, for all structural designs. Valmont® takes great care in each step of the design and manufacturing process to ensure that our customers receive the highest quality product and on-time delivery. By sharing manufacturing and engineering practices across our global network, Valmont® is better able to leverage its existing products, facilities and processes. As a result, Valmont® is the only company in the industry that provides a comprehensive product selection from a single source.

HEavier duty class equivalent poles ( greater than Class H1)

Engineering

Rapid Response™ Class Steel poles are designed to CSA, ASCE and NESC Standards, fabrication and quality meet or exceed AWS and ASTM Standards

Steel poles are uniform in size, taper and repetitive in pole design, with no cracks, knots, or splits

Delivery

Industry-leading turnaround times are supported by onsite inventories of steel coil at Valmont®’s numerous dedicated steel utility sites

A supply of steel-finished shafts promotes rapid response to emergency situations

Weight

Steel poles are at least 50% lighter than wood for easier handling, lower transportation and construction costs

Drilling

Steel poles offer Knockout™ holes that eliminate field drilling operations and pole whistle by utilizing only the holes required for a specific installation

Steel poles can also be drilled and modified in the field

Climbing

Steel poles can easily be climbed by adding optional climbing attachments such as ladders or steps

Maintenance

Steel poles eliminate the need for excessive retightening of hardware due to pole shrinkage

No expensive inspection and toxic treatment programs are necessary for steel pole applications

Catastrophic Failures

Steel poles are less subject to cascading type failures from a single downed pole than wood poles due to the consistent and predictable strength attributed to these products

Fire Resistance

Steel poles are fire resistant and reduce the liability associated with ground and pole top fires, providing greater reliability to the grid and greater safety to crews and to the public

Ground Line Protection

The use of galvanization, ground sleeves and 100% solid polyurethane coating has proven to be an effective deterrent against corrosion*

*Below-grade protection needs to be determined by the utility as it depends on different factors such as soil drainage and soil corrosion potential characteristics

Material Deterioration

Steel poles offer a valuable alternative by mitigating pole performance issues caused by timber rot and fungi growth, decay by insect damage, material loss due to woodpeckers and damage due to ultraviolet exposure

Impact Resistance

Steel poles offer exceptional resilience to surface impacts from minor handling and transportation damage to extreme events such as vehicle strike incidents

The failure mode of steel materials is different than wood or fibreglass in that the material yields and deforms in shape while typically remaining upright and in service

Inspection

Steel poles offer the value of less invasive inspection techniques and are more focused on surface conditions. Advanced inspection techniques exist for below-grade inspection and time-lapse material monitoring systems

Environmental Concerns

Steel poles contain no harmful preservative treatment chemicals to maintain their strength and extended service performance benefitting the users of poles in construction and the public domain which may have interaction with poles

Sustainability

Steel poles are non-toxic and have 75-100 percent recycled steel content at manufacture

They pose no disposable issues and offer a long-term solution for regulatory pressures to buy recycled and recyclable materials

Steel poles can be re-purposed within their service life and are recyclable at the end of service life

Life Cycle Cost

The life expectancy of steel poles is two to three times that of wood, providing a cost avoidance associated with future installation, maintenance and troubleshooting over the life of the structure

HEavier duty class equivalent poles ( greater than Class H1)

The AISI/SDMI’s 11402 release of the ‘Get Current’ bulletin has some great things to say about the advantages of using steel poles over wood from a lineman’s perspective. The bulletin tackles issues regarding steel pole reliability, their maintenance, environmental concerns and even lineman training. Check out some of the things they have to say about steel poles:

“A utility company relies on a strong and resistant overhead sub-transmission and distribution system to deliver electricity to its customers through wind, snow, sleet, fire and rain. Today, over 185 million electric distribution poles line the streets and open terrain of North America. Steel utility poles carry electric, telephone and cable TV services to keep customers safe, productive and in touch. Keeping these services online is essential to daily living. Steel poles help build a reliable and cost-effective distribution system — a system that will deliver electric power and access to communication when and where they are needed.”

Download the brochure to get more insights from the SMDI:

The Steel Market Development Institute (SMDI) is a business unit of the American Iron and Steel Institute (AISI), focused on advancing the competitive use of steel by meeting the demands of the marketplace for new and innovative steel products and solutions. SMDI provides technical support in areas such as automotive, construction, energy, packaging, and transportation, and promotes the sustainability and environmental benefits of steel.

The Wooden Distribution Utility Pole Shortage

Everyone loves a good, sturdy, wooden utility pole. But what if there were no poles to be had? We must talk about the current wooden utility pole shortage:

Firstly, the increased capital spending of electrical utilities places an ever-increasing demand on the limited supply of wooden utility poles.

Secondly, extreme weather events such as hurricanes and wildfires have caused significant damage to the existing infrastructure, further increasing the demand for replacements.

Finally, there is a limited number of suppliers of wooden poles, and some of them have been impacted by consolidation and acquisition in the industry.

Read our dedicated article about the wooden distribution pole shortage here:

The Penta Ban - what’s next?

The recent changes to the legislation behind the chemicals used during wooden pole treatment resulted in great uncertainty in the market. About half of the 137 million wooden distribution poles in North America are treated with Pentachlorophenol, also known as PCP or Penta in the trade. In 2015, the Stockholm Convention banned Penta, classifying it as a persistent organic pollutant.

On October 4th, 2022 Health Canada published a ‘Re-evaluation Note’ as an update to inform the public of the cancellation of all products containing pentachlorophenol.

Impact resistance, especially during Vehicle Strikes

Steel utility poles have several benefits during vehicle strikes compared to traditional wooden poles. Firstly, steel poles are much stronger and have a higher bending and buckling strength, which reduces the chances of the pole breaking or collapsing on impact. This can help prevent damage to surrounding infrastructure and reduce the risk of injury to people in the vicinity. While wood poles tend to shear, steel poles will typically bend when impacted, keeping the energized lines upright and away from the vehicle. Additionally, steel poles are able to absorb more energy during a collision, which can reduce the force of impact and further minimize the risk of injury. Finally, steel poles are resistant to fire, rot, and insect damage, which can help maintain higher levels of impact resistance over the course of their lifecycle. Overall, the use of steel utility poles can improve the safety and reliability of the power grid, as well as the general public.

VALMONT®’S Rapid Response™ Steel Utility Poles

Sometimes you don’t need custom engineering or special manufacturing. Sometimes, you just need a pole. And you may even need it in a hurry. The Rapid Response™ pre-engineered product line offers the most comprehensive pre-engineered steel structures in the industry. Rapid Response™ V-Series is the ideal solution for standardized structures larger than H10 and are available in round or 12-sided steel. Complete catalogue poles from Class 5 to V-20 are available in PLS-POLE for use in quick line design and emergency project response engineering.

With Rapid Response™ from Valmont® Utility, you get more than just a pole:

Pre-engineered uniformity

Reduced maintenance costs

Rapid speed to market

Increased structural life expectancy

Download the official Valmont® Rapid Response™ brochure from here and learn more about features, benefits, groundlines, classification, and more:

GALLERIES

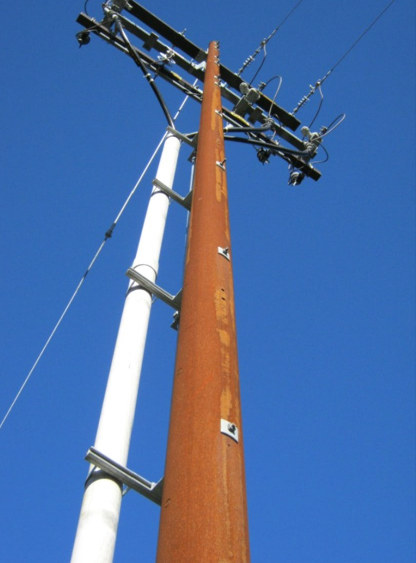

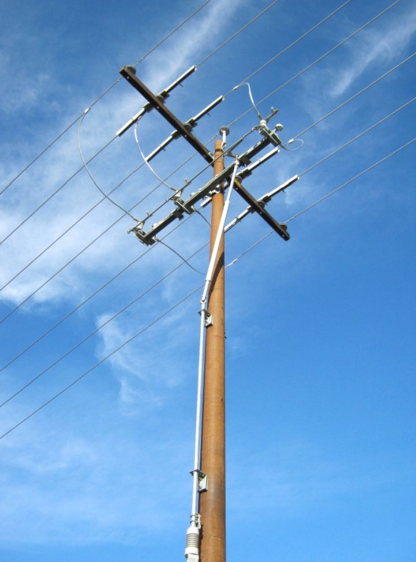

Energized Installation of Valmont®’s Rapid Response™ Class Poles

To find out more about Valmont®’s other products, click here:

For pricing, delivery, or more product information: