Implosive Sleeves Corporation

/about ISC

Implosive Sleeves Corporation brings over 30 years of experience in the conductor splicing industry, delivering innovative implosive splicing solutions backed by deep expertise in manufacturing, licensing, logistics, training, and field installation. With a manufacturing facility based in Ontario, Canada, the company supports utilities and contractors with locally produced solutions, hands-on technical support, and proven technology designed for reliable, efficient high-voltage conductor splicing.

Implosive connectors by isc

Full Tension Splices

Dead End Joints

Jumper Terminals

Implosive splices are available in several types, including Dead End Joints, Jumper Terminals, Full Tension Joints, and Anchor Terminations. These splices are compatible with a wide range of commonly used conductors and steel ropes, such as:

ACSR (Aluminum Conductor Steel Reinforced)

ACSR (Aluminum Conductor Steel Supported)

AAC (All Aluminum Conductor)

AAAC (All Aluminum Alloy Conductor)

ACAR (Aluminum Conductor Alloy Reinforced)

AASC (Aluminum Alloy Steel Conductor)

Steel guy wire (ranging from 0.5 inches to 1.5 inches)

Aluminum conductors (ranging from 50 mm² to 1584 mm²)

Steel conductors (ranging from 39 mm² to 900 mm²)

This ensures a versatile solution for a range of applications in electrical and structural installations.

services

accessories

ISC provides all the necessary accessories for installing implosive connectors (ie.: detonators, shock tubes, initiators, magazine log books, blasting log books, and anvil cutters for cutting shock tubes).

packaging

Implosive connectors are stored in robust, stackable, weatherproof wooden boxes.

They remain durable in all weather conditions and are easy to handle in challenging field conditions.

Each box is lightweight enough for one person to carry, and every one includes a field installation manual.

storage

Implosive connectors must be stored in magazines that are specified and licensed in accordance with NRCAN/ERD requirements, BNQ 2910-500 (2015).

ISC will assist you in obtaining the necessary licenses for your magazine and, if required, for a separate compartment for detonators.

If portability is a priority, the magazine can be mounted on axles for transport.

training

ISC will take great care in instructing line crews on proper installation techniques and product safety.

A classroom session offers a comprehensive review of the relevant regulatory requirements governing the safe handling, storage, and transportation of implosive sleeves.

A field training session provides practical, hands-on experience, giving trainees a solid understanding of the process involved in installing implosive sleeves.

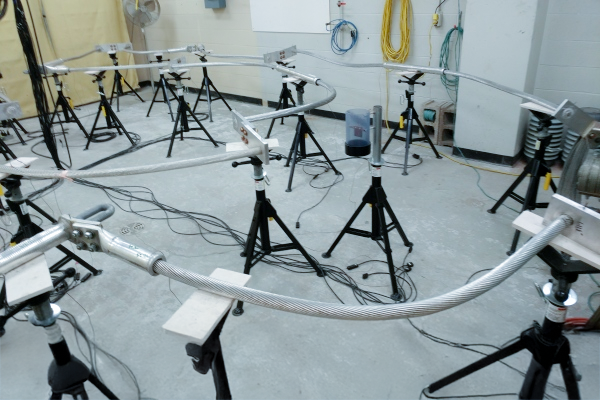

testing

All products are tested in independent, accredited labs. Testing includes:

Tensile Load Test to IEC 61284 Cl11.5.1

Electrical Current Cycling Test to IEC 61284 Cl 13

Visual Corona Test to CSA C83

Radio Influence Voltage Test to CSA C108.3.1

Impact Test to ASTM A370, E23

Weld Crack Test to ASTM E1471

support

Implosive Sleeves Corporation provides around-the-clock technical support to ensure customers have the guidance they need, whenever and wherever it’s required.

The team also works closely with customers to plan and manage inventory requirements, drawing on decades of industry experience to anticipate needs and reduce uncertainty.

This service-focused approach helps customers operate with confidence, knowing expert support is always close at hand.

recent projects

Pretium BruceJack Mine

Crest to crest mountain stringing, up to 4km

EHS Aluminum Clad Steel Wire, 32.7mm

1005.8 kN rating

QTY 1,100 pcs

On-time delivery

Rush delivery to replace failed hydraulic connectors

Bipole III

AASC (Aluminum Alloy Stranded Conductor)

38.01mm

214 kN

QTY 7,200 pcs

Delivered ahead of schedule

Ice Storm Emergency Repair

Oriole ACSR

Pigeon ACSR

7.2mm steel wire

QTY 200 pcs

Rush delivery

East West Tie Line

Grackle 192.5 ACSR

Alumoweld 19#10 OHGW

QTY 3,900 pcs

On time delivery

representation

ISC operates a manufacturing facility in Ontario for the production of implosive connectors, and works closely with VP Metall in Norway.

Composite Power Group is proud to be representing Implosive Sleeves Corporation across Canada, with the exception of Manitoba and Saskatchewan.

If you would like to learn more about ISC, please visit their official website:

For pricing, delivery, product information about implosive splicing, please contact us: