Northern Transformer

/About the company

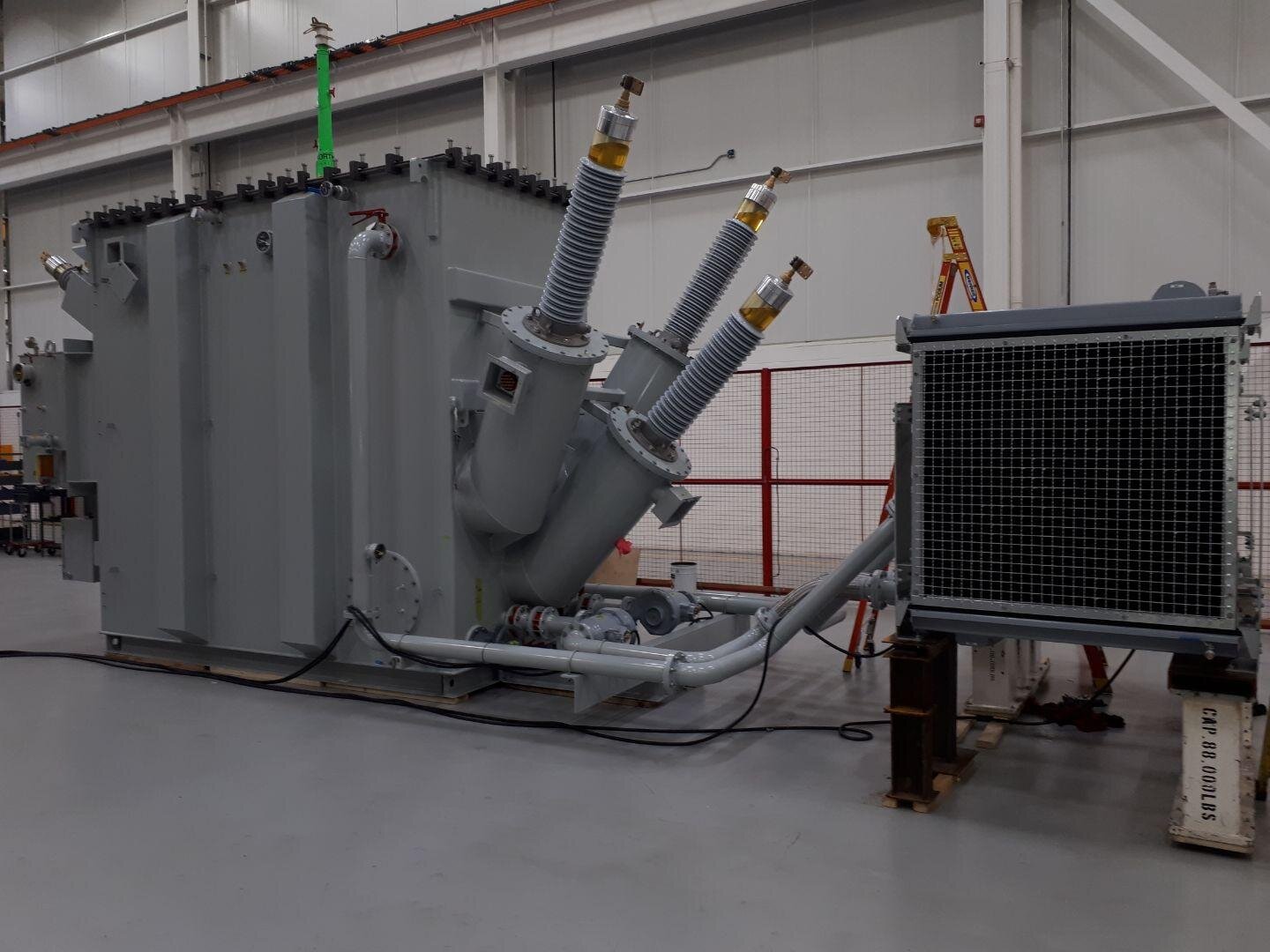

Northern Transformer’s Maple Ontario manufacturing facility comprises of 90,000 sq. ft. factory space with another 15,000 sq. ft. of office space for engineering and customer support. Adjacent to the factory is an additional 55,000 sq. ft. of production expansion space. Northern Transformer’s primary focus is the design and manufacture of liquid filled Power Transformers, Grounding Transformers and Specialty Transformers ranging from 5MVA to 200 MVA with a maximum primary voltage of 260kV (1050kV BIL).

Power Transformers 5-200 MVA

Every Northern Transformer liquid filled power transformer is built to the customer’s specific needs taking great care to meet and exceed industry standards applicable for that customer’s region such as CSA C88 M90, ANSI C57.12.00, IEC and IEEE.

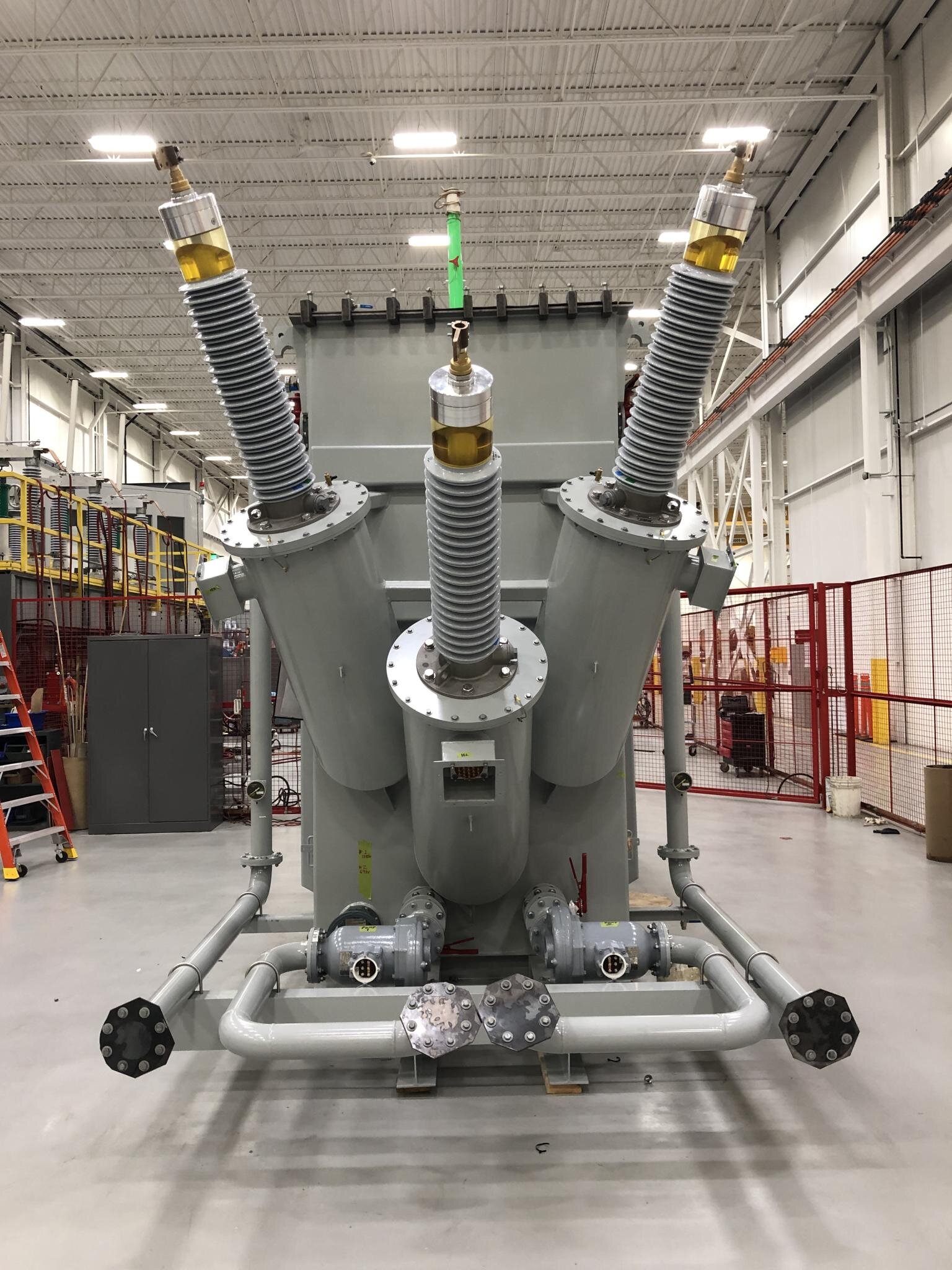

Northern Transformer designs, manufactures and tests power transformers in North America up to 200MVA and 260kV. The transformers are customizable with bushings being cover or side mounted with custom junction boxes or bus ducts to match existing and new infrastructure. In tank or compartment style DETCs (De-Energized Tap Changers) or ULTCs (Under Load Tap Changers) are available for either low voltage or high voltage windings depending on your requirements.

Tank

Tank welding is performed to CSA’s W59-M1989 requirements and a dye penetrant leak test is performed on all welds and seams to identify and eliminate any leaks. To ensure a long tank life, tanks are shot blasted with metal beads to a white metal and immediately primed and painted to a minimum of 5 mm thickness using a UV resistant two-part epoxy or powder coated. All tanks are engineered and manufactured to withstand full vacuum.

Coils

All coil winding is performed by hand by our skilled winders with decades of experience. Our experienced winders can detect naturally occurring defects in the conductor and address them prior to the transformer assembly process. Depending on the customer’s preference, we use copper or aluminum conductor and winding types of layer, foil, disc and helical. Each winding type has its own merits and we are happy to explore the different design options with our customers.

Assembly

Great care is taken into our assembly work. All insulation material is of the highest quality and tolerances are selected to ensure longevity and higher BIL withstand than typically found in the market. For paper wrapped conductor insulation, Northern Transformer uses Thermally Upgraded Kraft paper and we offer our customers the option of using premium winding insulations such as Nomex to increase longevity of the transformer.

Core

Northern Transformer’s designs are primarily based upon a three limb cruciform core design. Where customers require lower core losses (No Load Losses) or have noise concerns, higher grade core steel is available. For larger transformers, various core cooling options are available.

To learn more about Northern Transformer follow the link to visit the official website:

For questions, pricing, delivery times, more product info or product demo contact us

Click here for a printable PDF brochure about Northern Transformer and their products