Copperweld

/Product Range

Copperweld is a leading manufacturer of bimetallic products, specializing in power and grounding conductors for building construction, power grid, utilities, communications, and transportation. For over 100 years, Copperweld’s mission has been to create the most reliable and innovative wires on the market.

Copperweld’s metallurgical expertise and value engineering approach have resulted in the production of bimetallic products that have revolutionized various industries. Their facilities, located in the mid-south of the USA, manufacture bimetallic power and grounding conductors, which are distributed worldwide.

The culture of excellence and innovation that inspired Copperweld’s first products over a century ago continues to drive them today. Their team of engineers is constantly seeking better ways to test, manufacture, optimize, customize, and support the products they deliver.

The Power Grid Portfolio

Composite Power Group represents Copperweld’s Power Grid portfolio in Canada, which is specialized for the utility market.

Century Grid

High-strength CCS conductor

Century is Copperweld’s flagship family of grounding conductors and structural cables, installed in the harshest environments for over 100 years. With twice the strength of copper, Century is used in applications where high tensile strength, corrosion resistance, and theft deterrence are required.

ArcAngel

Flexible, High-Performance CCS Grounding

ArcAngel is an IEEE-compliant CCS grounding conductor for substation grounding applications where electrical performance is critical, and flexibility is needed while still offering all the benefits of Century products.

Stingray

Flexible, Covered Stinger Wire for Pole-Top Transformers

Designed to reduce wildlife and incidental contact, Copperweld® Stingray™ wire is an easy-to-install, covered, CCS high-voltage cable for use between phase conductors and equipment bushings.

Sunray

PV inter-panel power conductor

Sunray is the most energy-efficient, cost-efficient photovoltaic (PV) wire on the market. These premium CCA conductors offer 3% greater efficiency than standard cables, which means more money in your pocket.

About the company

Copperweld®’s story is one of American innovation and determination. Throughout their 100 plus years, the one constant has been their workforce- dedicated and determined, they are the heartbeat of Copperweld®.

Since ancient times, mankind has been trying to combine the strength of steel with the non-corrosive properties of copper. In 1915, that idea became a reality. Copperweld® engineers discovered a molten-weld process for permanently bonding copper to steel. Ever since, their company has been considered the leader in innovation in the bimetallic industry. The original process was replaced by a solid cladding process in 1979.

Genuine Copperweld® Copper-Clad Steel (CCS) wire and strand have been utilized and relied upon for over 90 years as strong, non-corrosive, efficient grounding conductors. Combining the strength of steel with the conductivity and corrosion resistance of copper, Copperweld® provides a long-lasting, low impedance path to earth.

Copperweld® delivers outstanding reliability and performance in a variety of applications at every step in the power utility process: generation, transmission, and distribution of current.

Why choose copperweld?

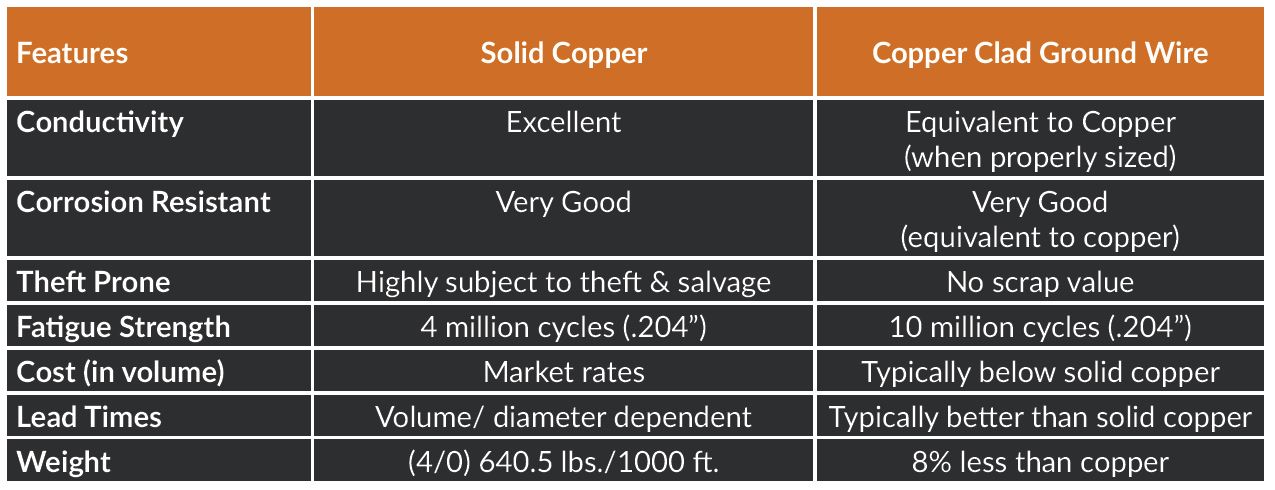

Advantages of choosing copper clad steel over pure copper wire:

- Theft deterrent

- Greater fatigue life – lasts longer

- Excellent current carrying capability (skin effect)

- Lower cost than copper

- Lighter weight than copper

- Installs the same as copper

- Improves safety management

Copperweld® wire is less susceptible to theft than solid copper because it is a bimetallic product and does not have the high scrap value of pure copper. The copper layer in our Copperweld® CCS cannot be removed, and so it is practically worthless to would-be black marketers.

CCS- PHYSICALLY STRONGER THAN COPPER

Copper clad steel actually performs better on the fatigue tests than pure copper wire.

ASTM B-193, ASTM B-452, ASTM B-227, ASTM B-228 and ASTM B-910 certified

RUS (Rural Utilities Service) listed

All bimetallic products are processed at the Copperweld®’s ISO9001 and ISO14001 certified facility in Fayetteville, TN

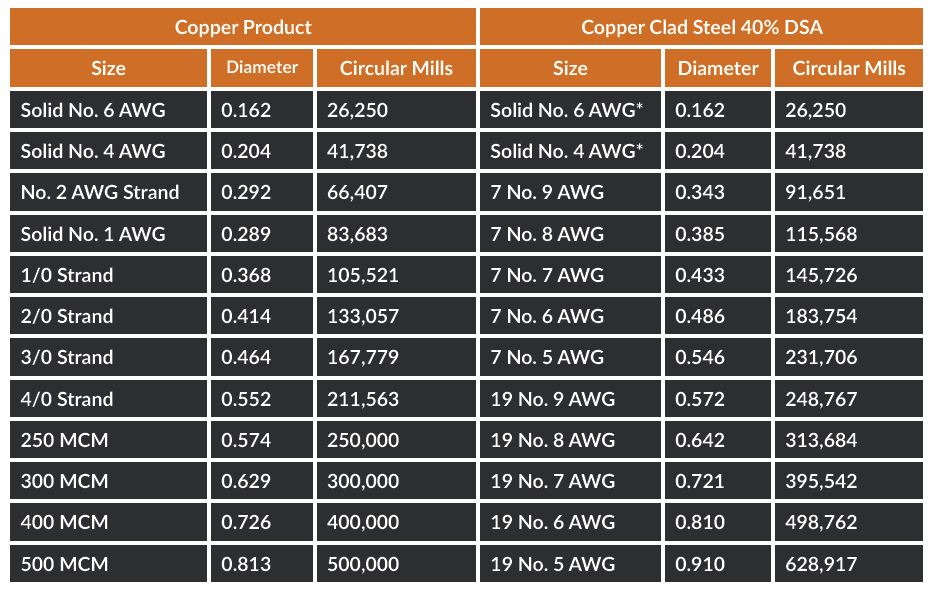

PROPER PRODUCT SIZING FOR COPPER CLAD STEEL GROUNDING APPLICATIONS

PHYSICAL AND ELECTRICAL PROPERTIES

To learn more about this vendor click here to visit their website!

For price, delivery, product demo or other questions click here!